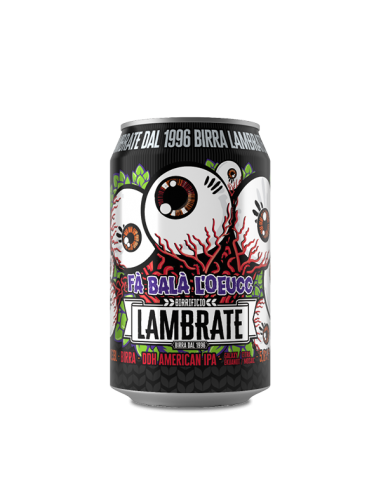

La Fa Balà L'Oeucc is the synthesis of the last years of work regarding hopped "Made in Lambrate," our point of view with respect to the concept of IPA in a contemporary key.

For this we have developed a pale ale with oats and rye characterized by the tropical fruit notes given by the double dry hopping.

For this beer, 4 hop varieties were used for a total of about 30g/l.

Available in cans only!

Acknowledgements:

2019 CONCOURS INTERNATIONAL DE LYON

2nd class. FA BALA L'OEUCC

BEER Ingredients: water, barley malt 17.0%, oats 2.0%, rye 2.0%, hops, yeast.

Brewed and packaged by:

BIRRIFICIO LAMBRATE S.R.L. Via Privata G.Sbodio 30/1 - 20134 - MILAN

Produced in a plant where wheat, oats and rye are used.

Keep in a cool place and away from light

Unpasteurized and unfiltered beer without added preservatives